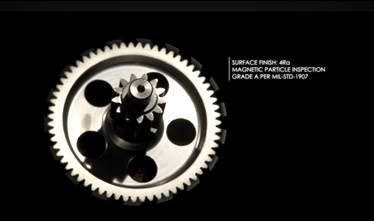

Custom Gearboxes

Design engineering support

- Comprehensive assessment and feasibility studies

- Reviews of tolerancing stack-up, backlash, hysteresis, total integrated error

- Life expectancy, speed, torque and duty cycle

- Load values, directions and vibration

Types: Speed increasing and decreasing planetary systems, Right Angle gearboxes, Spur gearboxes

| Smaller Sizes | Max Output | Max Input Speed | Max Radial Load* | Max Axial Load* |

| 6mm (0.25″) | 0.50 in-lbs | 3,750 RPM | 2 lbs | 1 lb |

| 10mm (0.39″) | 1.50 in-lbs | 5,000 RPM | 10 lbs | 6 lbs |

| 15mm (0.59″) | 6.0 in-lbs | 8,000 RPM | 20 lbs | 12 lbs |

| 40mm (1.56″) | 40-70 in-lbs | 5,000 RPM | 120 lbs | 40 lbs |

| 60mm (2.375″) | 160-200 in-lbs | 4,500 RPM | 150 lbs | 50 lbs |

| 90mm (3.5″) | 400-500 in-lbs | 4,000 RPM | 450 lbs | 150 lbs |

*Loads at 100 RPM

Any gearbox with a diameter larger than 90mm will be reviewed on a case-by-case basis.

These are general specifications and subject to flexibility depending on the application.

65,000 ft2/6038 m2 manufacturing campus in Farmingdale, New York

ISO 9001, ISO 13485, AS9100, ITAR

Prototyping: Precipart maintains a dedicated prototyping center that allows us to support our customers requiring quick turn proofs of concept

Gear Cutting: CNC and manual Gleason Pfauter, Fellows, Mikron & Barber Coleman machines for shaping and hobbing

Gleason Bevel Gear Cutting: Dedicated Gleason bevel gear cutting area

Grinding: CNC and manual Studer & Tschudin OD & ID grinders

Full complementary capability: CNC milling, large and small diameter turning, lathe, mill and drill

Assembly: 4,500 ft2 of temperature controlled with electrical outlets and compressed air at every assembly position. Fully equipped for mechanical and electromechanical assembly and testing. ESD compliant and J-STD-001 certified

Clean room: 1,000 ft2 10K certified clean room

Gear Inspection and Metrology: PECO ND 300 Gear CMM, 2 Brown & Sharp CMM, Keyence vision systems, Vision System, OGP Optical comparators, over 60 gear testers, 150+ master gears

Passivation: Robotically controlled citric acid passivation